Numerous different approaches

How do companies in the fittings industry actually approach innovation? Where do the ideas come from? How are they tested and implemented? There are very different approaches here. At the Oventrop company from the Sauerland region, innovation management is the responsibility of the Advanced Development department. There the ideas are collected, evaluated with regard to their market relevance and further developed in workshops. "First of all, it is checked whether an idea, for example for a new valve, has technological or cost advantages or leads to a simplification of production. If certain boundary conditions are met, the idea is transferred to the innovation roadmap as a project. A sketch is then produced to show the installation space and functionality. The pre-development department then passes on a product designed in the initial stages to series production, which sharpens it up and considers, among other things, how best to manufacture it," explains Florian Wiemeyer, Head of Marketing Service at Oventrop.

At Franke Aquarotter, product developments are realised within the framework of strict project management. In this way, the manufacturer of fittings and systems for the public and commercial sectors is reacting to the increasing speed of business. A milestone plan is drawn up for each project, ranging from the initial idea to the evaluation of the new product one year after market launch. Currently, 33 milestone projects are being pursued in parallel and with different priorities. These are not always new developments, but also revisions of products at the end of their life cycle. "We also work with sprint workshops", explains Marketing Director Verena Töpfer-König, "at the beginning of the workshop there is an idea, which is worked on in the course of the workshop to such an extent that at the end you have a first visualisation of the product, a kind of dummy". This workshop result is then incorporated into a project plan.

At Dornbracht, innovations are primarily concerned with the major megatrends. For some time now, the focus has been on sustainability, healthiness, and individualisation. "Actually, we are selling a water experience. And the fitting is a medium, a tool to do justice to water, to shape, design and control it", says Holger Struck, company spokesman at Dornbracht. The development of ever newer innovations requires an intensive and ongoing examination of technological progress and its possibilities, as well as a comparison with people's needs. "On our company premises in Iserlohn, we have given the necessary processes the appropriate space: The proximity of research and development to sales and customer service is organised in a module park. This facilitates direct exchange," says Struck.

Impulses come from outside

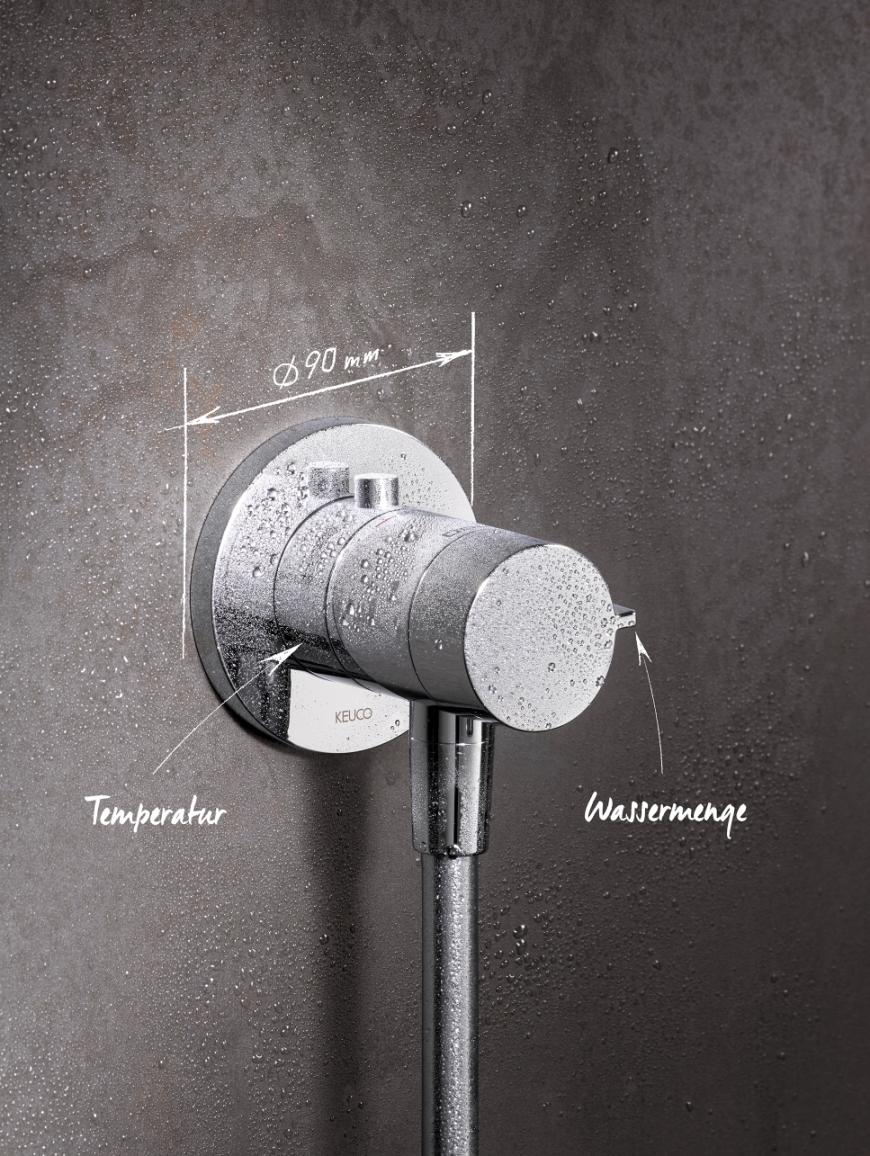

Not every idea for an innovation originates in the company. Important impulses often come from outside. "As part of our innovation management we regularly exchange ideas with designers, architects and sales specialists. There, it is primarily a matter of identifying topics that will play a role in the future," says Dirk Hagedorn, Head of Marketing and Product Development at bathroom supplier KEUCO from Hemer. The sanitary specialist MEPA is also convinced that ideas can also come from outside. The company receives many suggestions from its customers, i.e. the installers, who are therefore also included in the optimisation processes for the products. This often involves innovative installation techniques that can save a lot of time on a construction site. MEPA bundles the suggestions and ideas of external specialists in the development department. Ideas and suggestions for improvement from within the company are collected and evaluated in the company suggestion scheme.

Saving resources with new ideas

The conservation of resources has become a social megatrend. For this reason, the topic of sustainability is becoming increasingly important in innovations in the fittings sector. New or improved products must be more efficient, they must be able to score points by using less water and less energy, they must be robust and durable so that materials can be protected. "But sustainability always brings economic benefits, because it reduces operating costs," says Töpfer-König. The idea of conserving resources is also becoming increasingly widespread at the design level. Innovations that only satisfy a brief trend are not sustainable because they waste resources in planning, personnel, production and, of course, materials. Struck from Dornbracht puts it in a nutshell: "We need sustainable aesthetics.

|

|

|

|

||||

| KEUCO |

Blue Responsibility box: Under the umbrella of the Blue Responsibility sustainability initiative, leading brand manufacturers in the industry, who are members of the VDMA Armaturen, provide information about their sustainable corporate philosophies. Blue Responsibility is an expression of their common self-image of responsible use of our natural resources. You can find out more about this at https://www.blue-responsibility.net/.